- // Our Trainings

Lean Six Sigma

Green Belt

Contact Us

The Six Sigma quality management tool was created by engineer Bill Smith with the support of CEO Bob Galvin in the 1980s at Motorola to increase business performance. Shortly thereafter, the Chairman of GE Jack Welch adopted the six sigma methodology and connected its results with executive compensation and return on investment (ROI); also publishing its financial benefits in their annual reports thus, making it a worthy tool. Originally, Six Sigma was concerned with issues during the production process; however, a variant called Lean Six Sigma evolved at Toyota and considered not only manufacturing, but other facets of their business processes as well. Lean concepts were already being used by Toyota since sixty’s. The lean methodology however was fundamentally applied much earlier by both Ford and Boeing in the early 1900s. Since both tools contributed to the improvement in business process and performance, the line between both Six Sigma and Lean blurred to the point that Lean Six Sigma came into existence and can be used beyond manufacturing for a number of different industries.

Lean Six Sigma Green Belt

$59.99

$78.98

The Six Sigma quality management tool was created by engineer Bill Smith with the support of CEO Bob Galvin in the 1980s at Motorola to increase business performance. Shortly thereafter, the Chairman of GE Jack Welch adopted the six sigma methodology and connected its results with executive compensation and return on investment (ROI); also publishing its financial benefits in their annual reports thus, making it a worthy tool. Originally, Six Sigma was concerned with issues during the production process; however, a variant called Lean Six Sigma evolved at Toyota and considered not only manufacturing, but other facets of their business processes as well. Lean concepts were already being used by Toyota since sixty’s. The lean methodology however was fundamentally applied much earlier by both Ford and Boeing in the early 1900s. Since both tools contributed to the improvement in business process and performance, the line between both Six Sigma and Lean blurred to the point that Lean Six Sigma came into existence and can be used beyond manufacturing for a number of different industries.

Contact Us

The Six Sigma quality management tool was created by engineer Bill Smith with the support of CEO Bob Galvin in the 1980s at Motorola to increase business performance. Shortly thereafter, the Chairman of GE Jack Welch adopted the six sigma methodology and connected its results with executive compensation and return on investment (ROI); also publishing its financial benefits in their annual reports thus, making it a worthy tool. Originally, Six Sigma was concerned with issues during the production process; however, a variant called Lean Six Sigma evolved at Toyota and considered not only manufacturing, but other facets of their business processes as well. Lean concepts were already being used by Toyota since sixty’s. The lean methodology however was fundamentally applied much earlier by both Ford and Boeing in the early 1900s. Since both tools contributed to the improvement in business process and performance, the line between both Six Sigma and Lean blurred to the point that Lean Six Sigma came into existence and can be used beyond manufacturing for a number of different industries.

Instructors

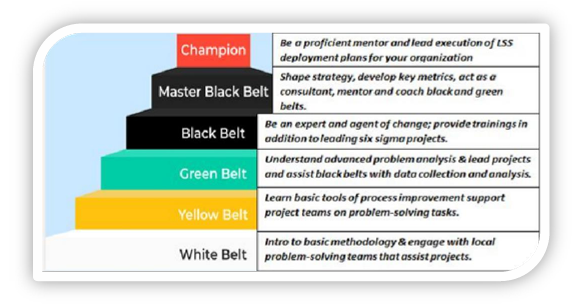

LSS certification model is divided into different “belts” to acknowledge varying levels of knowledge and proficiency in applying Six Sigma methodologies. There are five belt levels in the LSS certification mode —White, Yellow, Green, Black, and Master Black and a Champion level as well each representing a different skill and experience level.

Think and Act Efficiently and Effectively as you dive in the world of Six Sigma!

As an individual:

- Gain extensive knowledge on problem solving and quality management

- Add value to your career and stand out among your competition

- Rise to a leading position and get an industry standard salary

- Add value to your company and improve business process

As a team for your organization:

- Improve productivity, reduce operational cost and achieve business excellence

- Have a competitive edge and gain customer satisfaction

- Build smart teams to achieve targets

- Master problem solving skills and streamline your processes with success

- Gain global recognition by maintaining and sustaining sigma standard

The Lean Six Sigma Green belt is the third belt after white and yellow. This certification enables you to be a well versed lean sigma expert who has knowledge of all key elements of lean six sigma methodology. As a green belt professional, you understand all aspects of Lean Six Sigma method including competence in subject matters contained within the phases of Define, Measure, Analyze, Improve and Control (DMAIC).You are able to analyze and solve quality problems, do a quality improvement project or be a part of complex opex project led by a certified black belt.

You can take the green belt certification directly, but it is preferred that you go through a white and yellow belt for better learning experience. But as mentioned these are no prerequisites because white and yellow belt topics are covered in the Green Belt training.

So, get ready for green belt and gain insights into the fundamental concepts of Lean and Six Sigma, explore real-time projects, and witness firsthand knowledge by applying DMAIC to your project. Brace yourself for a transformative experience that will empower you to think and act efficiently and effectively with lean sigma mindset!

- Professionals who want to learn and implement the lean practices in their organization

- Anyone who wants to learn about productivity improvement, problem solving and performance improvement

- Anyone seeking a career in quality, performance management and operations management

- Process Quality Engineers, manufacturing engineers, Continuous Improvement specialists, Quality excellence manager, operations excellence manager, LSS project lead, lean managers and six sigma project consultants.

Day 1:

- Introduction to lean six sigma

- DMAIC

- Define Phase-Project Charter, CTQ, and SIPOC

- Project Selection by group and application of Define Tool

Day 2:

- Change management and stakeholder analysis

- Measure Phase-Data Collection

- Basic Statistics Standard Deviation

- Baseline Sigma Calculation

- QA Discussion

Day 3:

- Analyze phase – VANVA, Process mapping Cause & Effect diagram/Matrix

- Pareto Analysis with Exercise

- Control Phase Documentation

- Process management charts

- QA Discussion

Day 4:

- Data Collection

- Sigma Level Calculation

- Introduction-Improve Phase

- FMEA

- QA Discussion

Day 5:

- Brainstorming Techniques and Pilot

- Introduction to Minitab

- Basic Analysis in Minitab with Exercises

- Project Reviews Presentations by Participations

Day 6:

- Introduction to Control Phase

- Control Charts-XbarR. X-MR, p, np, c, and u chartsb

- Control Chart Exercises On Minitab

- Final QA session

Day 7:

- Minitab

- Project discussions

Day 8:

- A complete review

- Exam discussions

*Project and an exam by end of the training to get LSSGB certificate*

“The Agenda shows the topics to be covered during the program. The trainer can change the timings or schedule of the topics as per the specific requirements of the trainees. However, it would be always ensured that all the topics are covered the training”

Adnan R. Ahmed is a USA Graduate, Professional Master Trainer, Facilitator and Expert working in the field for 20 years. Mr. Ahmed has extensive experience in multiple career dimensions such as Project Management, PMO, Operational Excellence, Lean Six Sigma, Quality, Risk Management and Business Continuity Management.

Mr. Ahmed is certified CBCI, PMP, ITIL, Lean Six Sigma Master Black Belt (LSSMBB), ToT, Senior Lead Implementer and Senior Lead Auditor – Business Continuity ISO 22301, Lead Auditor ISO 9001, Balance Scorecard Professional, Apollo Risk Analyst.

Mr. Ahmed prepares his case studies and exercises for each course which are highly appreciated by all participants.

- Implemented Business Continuity in 4 Business Units (Aluminum, Phosphate, Gold) of Ma’aden with High Risk Impact up to 20 Million Dollars in 2023

- Trained BC Team members and conducted BC Exercises for Islamic Development Bank – Conducted 5 Kaizen Projects for Rolling Mill, Procurement and Supply Chain of savings worth 2 Million Dollars in 2020

- Developed Lean Six Sigma inhouse application from end- to-end methodology implementation of all phases in 2019

- Executed Lean Six Sigma Program with 119 candidates and 63 projects with estimated savings of 5 Million Dollars in 2018

- Trained more than 5,000 professionals in PMP, ITIL, LSSGB, LSSBB, Leadership and Soft Skills in 10 years by 2017

- Build IT PMO for Ministry of Water and Electricity in 2014

- Implemented ITIL for NADEC in 201

- Worked for Two Programs of the Vision 2030 Strategy at King Saud University in 2010

- Established a Training Department in Marcom in 2008